The Ontario regulation that limits concentrations of contaminants caused by air pollution have been revised to improve environmental protection and modernize the permitting system.

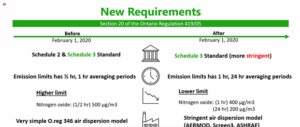

The more stringent air contaminant concentration standards are in accordance with Ontario Regulation 419/05 (O. Reg. 419/05), under the Environmental Protection Act. As a result of the stricter standards, industrial facilities that were complying with the Air Pollution – Local Air Quality Regulations prior to 2020 may not realize that they are now out of compliance.

Char Technologies Ltd., a leading cleantech development and environmental services company based in Toronto, Ontario, recently provided an informative webinar on key changes to air permits in Ontario. John Nicholson, senior environmental engineer with Char Technologies, moderated the participation of Paul Manning, certified environmental law specialist with Manning Environmental Law, and Elham Gorouhi, senior project engineer with ALTECH Environmental Consulting Ltd. ALTECH is a subsidiary of Char Technologies, and offers various services in consulting and permitting for water, waste and renewable energy.

From left to right: Elham Gorouhi, senior project engineer with ALTECH Environmental Consulting Ltd.; John Nicholson, senior environmental engineer with Char Technologies; and, Paul Manning, certified environmental law specialist with Manning Environmental Law.

The panelists provided an insightful overview of the revised regulation – including air contaminant concentration standards for all Ontario facilities as of February 1, 2020 – and advice on what steps need to be taken to be ensure compliance with the new requirements.

Manning kicked things off with an overview of the three compliance approaches for regulated facilities: meet air standards prescribed in the regulation; request, receive and meet a site-specific standard; or, register under and meet a technical standard (i.e., for certain industries such as foundries).

After outlining the types of air permits in Ontario – Environmental Compliance Approval (ECA) and Environmental Activity and Sector Registry (EASR) – he explained when facilities must develop an Emission Summary and Dispersion Modelling (ESDM) to show compliance.

“An ESDM report summarizes all the air emissions from the facility and uses air dispersion models, alone or combined with air monitoring data, to assess compliance,” explained Manning.

A facility must develop an EDSM report if:

- Applying for an ECA

- Applying for a site-specific standard exceeding an Upper Risk Threshold

- Requested by notice from the Ministry of the Environment, Conservation and Parks (MECP); or

- In a sector listed in Schedule 4 or 5 of the Regulation

Reports must be updated annually and be accurate as of December 31st in the year the report was prepared. Updates must be completed no later than March 31st in the following year.

Manning warns that the reporting deadlines have not been made “crystal clear” so it’s important to take note of these expectations.

Key revisions to requirements

Key changes to note as of February 1, 2020 include the following:

- Schedule 3 concentration standards apply to all facilities

- Older regulatory air dispersion models were phased out

- Facilities may only choose from SCREEN3 or AERMOD (American Meteorological Society/Environmental Protection Agency Regulatory Model) to assess compliance with the air standards in Schedule 3

- Facilities must also use the ASHRAE method to assess same structure contamination

Facilities submitting an ECA since February 1, 2019 were required to use the more advanced models.

What if you exceed the new standards?

“The problem with this is that you may have been complying with old standards and old dispersion models,” said Manning. “If this is the case, you have to take some important steps promptly.”

If the ESDM report indicates that discharges of a contaminant may exceed Schedule 3 standards or cause an adverse effect, said Manning, a facility must take the following steps:

- Notify MECP (s. 28 of the regulation)

- Submit within 30 days a written abatement plan that recommends steps to prevent and minimize discharges (s. 29)

- If an Upper Risk Threshold (URT) may be exceeded, immediately notify MECP local District Office and submit an ESDM report for that contaminant within three months (s. 30)

Manning also advises to note the prohibition on and duty to report discharges of contaminants above regulated levels (ss. 6 and 13 EPA).

Elham Gorouhi provided a detailed breakdown of the technical details of the new requirements and what facility managers should be aware of for the year ahead. With regard to the new permitting process, there were several recommendations provided.

“This new process is faster because the registration is online and the ministry review is not required,” said Gorouhi. “A registered, licensed engineering practitioner is required to sign and stamp and state its accuracy. This will also help the ministry to maintain their one-year service time for ECA application times.”

When calculating facility data, Gorouhi recommends considering the worst case scenario “because the production rates and manufacturing activities vary depending on the demand and they’re not consistent. So if you’re willing to show compliance for the worst case scenario of the facility then the compliance for the other scenarios are also evident.”

For further information regarding Ontario Reg 419/05, click here.