An energy technology project that converts wood waste into renewable natural gas has been successfully providing energy to homes and businesses in Edmonton, Alberta for six months in a demonstration project.

“The idea of converting wood waste into renewable natural gas has been worked on for over 20 years,” says Edson Ng, principal of G4 Insights Inc., the Vancouver, B.C.-based company developing and commercializing the process to produce renewable natural gas. “But we developed an alternate route that avoids a lot of the problems that were encountered with the gasification process. Our process takes forestry residues and converts them using a pyrolysis process.”

The clean tech project has been in development over the past decade. During the six-month demonstration project, G4 Insights converted forest residues into renewable natural gas and injected that gas directly into the natural gas distribution system operated by Canadian gas industry company ATCO. There are plans to expand this pilot into a commercial plant in three to five years.

Recent research indicates that renewable natural gas emits 85 per cent less greenhouse gas emissions than conventional natural gas.

Ng states that the G4 process can be used to provide an alternative energy source to fuel transportation or industrial processes, and it can used interchangeably by customers without any equipment modifications. He explains that the infrastructure is already available; gas produced from organic waste from farms, forests, landfills and water treatment plants is captured, cleaned and injected in the natural gas pipeline infrastructure to be delivered and used in the same way and with the same equipment and appliances as natural gas by homes and businesses.

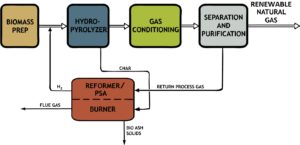

G4’s proprietary process, PyroCatalytic Hydrogenation (PCH), uses fast pyrolysis rather than gasification of the biomass to generate a vapor from the solid phase. This fundamental difference enables a low temperature thermochemical process consisting of the following components:

- Biomass preparation – Forest biomass is prepared by cleaning and partial drying.

- Hydropyrolysis – Biomass is vaporized in a pressurized hydrogen atmosphere by using a recirculating heating media to create a fast pyrolysis process. The generated vapors and aerosols are separated from the solid phase mixture of char and media. The char is further separated from the heating media for use in the reformer.

- Gas conditioning – The pyrolysis vapors are catalytically converted into methane and steam in the presence of hydrogen gas. This is performed at catalyst temperatures below 650 degrees Celsius and minimizes the formation of poly-aromatic hydrocarbons.

- Separation and purification – the hot gases are cooled in a controlled process and the methane gas is separated and purified from the liquids and remaining hydrogen.

- Hydrogen generation – A portion of the methane, water, and excess hydrogen is recirculated into a steam methane reformer to generate the hydrogen required for the hydropyrolyzer. The heat source for the endothermic reforming process is the combustion of the char generated in the pyrolysis process.

The project received $250,000 of support from Alberta Innovates, under the Alberta Bio Future program. The project also received $2.8 million in combined support from Natural Gas Innovation Fund and Natural Resources Canada, as well as in-kind donations from ATCO and FP Innovations.

“This project is a prime example of the innovation and tech Alberta needs to move forward in ways that benefit both the environment and the economy. It demonstrates renewable natural gas can be injected successfully into a grid, which creates opportunities for emissions reductions and results in consumers using cleaner fuels,” Environment and Parks Minister Jason Nixon told the Edmonton Journal.

To watch an interview with Edson Ng, principal of G4, click here.

For further information on G4, click here.